Tab And Slot Sheet Metal Design

- There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can use non-sheet metal feature tools, then insert bends or convert the part to sheet metal.

- In thin material like 3mm and under, non-structural, I like to run the tab flush with the top of the slot and just fuse it with TIG, no filler. For speed and strength, at least in thicker material, stop the tab at the mid point thickness of the slot and fill with a hot plug weld. In 3mm the slot isn't wide enough for this to be a good weld.

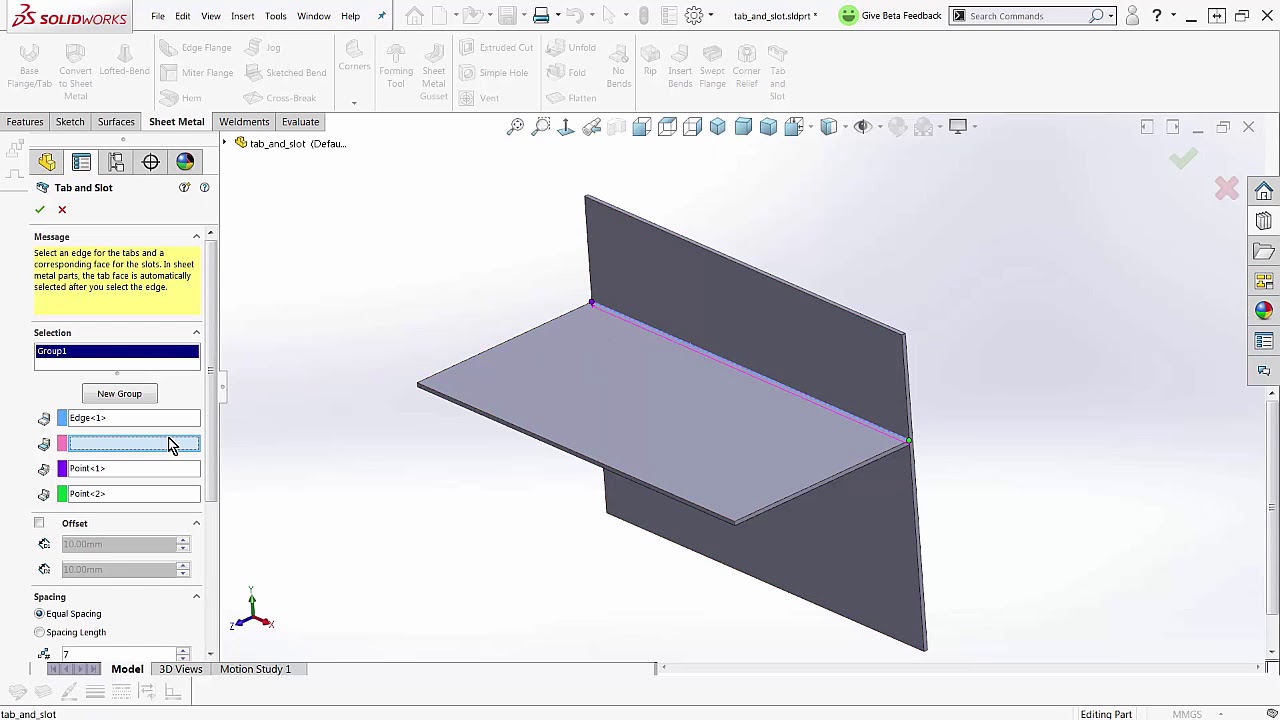

- Although the Tab and Slot command is found in the pulldown menu INSERT SHEET METAL TAB AND SLOT, it is not a command limited to sheet metal type parts. Tab and slot can be applied to any part file type, which makes it incredibly valuable for woodworking type projects. Check out the new Tab and Slot command in SOLIDWORKS 2018 and enjoy this.

Here's a handy carry-all for organizing tools. And it goes together without glue or fasteners.

In this article, we will introduce the 6 types of sheet metal joining process that is often used in product design. Folding / Tab Joints The two pieces of sheet metal connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. 1.1 Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.

This tool tote reminds me of the interlocking cardboard or sheet metal toys I had as a kid — the kind where you assembled them by 'inserting tab A into slot B.' Unlike those toys, this tote isn’t some flimsy box. Once all the parts are together, they interlock to form a rigid, sturdy assembly. What makes this even more amazing is the tote isn’t glued and you don’t need any hardware or fasteners to build it. Customized for You. Besides the easy assembly, you can customize the dividers and tool holders to suit your needs. In fact, if you’re like me, you might make two or three of these easy-to-build totes for specific tasks like hanging pictures, doing household repairs, or organizing craft supplies. And if you want to change the layout of the tote later on? No problem. The tote comes apart just as easily and quickly as it went together in the first place.

SELECT YOUR PLAN PACKAGE

- $9.95 Learn more

- Learn more

What You Get:

- 7 printable (digital) pages of step-by-step instructions

- Nearly 30 full-color photos, illustrations and exploded views

- Cutting diagrams

- Materials list

- Project sources

Note: After your purchase, you will receive an email containing a PDF attachment of your purchased plan, as well as instructions for logging in to download the plan and access any other associated files and videos, which will all be located on this page.

Product Recommendations

We don't have any links to project supplies and hardware for this particular project yet, but here are some other products that might be of interest to you. (We may receive commission when you use our affiliate links. However, this does not impact our recommendations.)

Similar Woodsmith Plans

Imperial Plans

The United States Customary System of Units (USCS or USC), more commonly referred to as the English or Imperial system, is the standard set of units for our plans. It uses inches and feet for measurement. This is the one you probably want if you are in the United States, and it is the one we have traditionally offered on this website.

Metric Plans

The International System of Units (SI), more commonly referred to as the metric system, is the alternative set of units that we have available for some of our plans. It uses millimeters, centimeters, and meters for measurement. This is the one you probably want if you are outside the United States. These plans are provided by our business partner, Australian Woodsmith, and are based on the original Woodsmith plan. However, dimensions and other elements of the plan may vary between the metric and standard versions. Be sure to double-check the plan before building.

Premium Plans

All of the information that you need to build our plans can be found in the standard plan. However, if you want even more granular detail to make your job easier, you should consider our premium plans. These come with additional shop diagrams that we drew when creating the prototypes. Shop drawings are not available for every plan.

Affiliate Link

Since you are an affiliate, you can use this url to link people to this page and get credited for it:

If you want to use an image thumbnail link, you can copy and paste something like this into the source code of your page:

Affiliate link unavailable.

Marx made five different type of couplers between 1934 and 1974. If you’ve never seen Marx couplers explained before, here’s a primer on how to identify them and use them together. And I even have a few repair tips if you need them.

Tab and slot

Sheet Metal Tab And Slot Design Guide

You’ll see tab and slot couplers more often than any other type. Some people also call them hook and slot couplers, or simply hook couplers.

These couplers are formed out of sheet metal, allowing the tab to mate with the slot of the coupler on the adjacent car. This design was simple and effective, and most makers of trains used some form of this design or another prior to World War II.

Marx introduced this style of coupler in 1936 and continued to use it until the end in 1974, although Marx relegated it to locomotive-to-tender connections after 1972. Marx may or may not have used it longer than anyone else, but they were the last of the big-name train manufacturers to stop using it in the United States. It wasn’t very realistic, but it was inexpensive and effective. It’s also compatible with a number of other coupler types, so a Marx car outfitted with these couplers makes a useful transition car so you can run more than one type together.

Marx had some variants on this design. Cars intended for electric train sets had their couplers attached via a brass eyelet. Cars intended for clockwork-powered train sets had their couplers attached via tabs or a dimple that allowed them to slide. Clockwork locomotives like some slack in the couplers, as it makes it easier to get the train started. Electric sets work better without that much slack. The small amount of slack you get from fixed couplers is adequate for electric sets.

Sliding couplers can be prone to hanging up. Here’s my simple fix for that.

Compatible with: Joy Line (if height permits), plastic knuckle, plastic tilt.

Joy Line

Early Marx or Girard Model Works sets had a hook coupler with a round hole and a t-shaped hooked tab. Early American Flyer and Hafner trains used a similar design. It works the same way as the later tab and slot coupler and they will couple together if the height matches closely enough. This design lasted until 1935.

The later tab and slot design has less slack in it, which makes it more reliable. It is less likely to accidentally uncouple. The advantage to the earlier design is that it was easier for young children to use.

Compatible with: later tab and slot couplers and plastic knuckle couplers, if height permits

Tilt or fork

The tilt or fork coupler dates to 1942. Marx kept making it all the way to the end of its train production, in 1974. It was Marx’s top of the line coupler.

All of the train makers wanted a coupler design that could automatically couple or uncouple to improve play value. The tilt coupler was Marx’s second and more successful effort. Tilt couplers will automatically mate by running the cars into each other, as long as their height is close.

Tab And Slot Sheet Metal Designs

It’s a good idea to check your metal tilt couplers’ height against a plastic tilt coupler for smoother running. You can adjust the height slightly by gently bending the coupler up or down.

Later tilt couplers made of plastic had a slot in them to make them compatible with tab and slot couplers. When Jim and Debby Flynn licensed the name Marx Trains and started producing trains in the old Marx style, they included a slot in their metal coupler. Some hobbyists cut a slot in their metal couplers with a Dremel cut-off wheel so they can attach a tab and slot coupler to them. A small cut at the back of the existing opening suffices.

Both types of tilt couplers are completely compatible with one another.

Sheet Metal Tab And Slot Design

If you ever need to remove or replace the spring in a tilt coupler, it can be difficult, but there’s a trick that makes it much easier.

Compatible with: Tab in slot couplers (plastic tilt couplers only)

Knuckle

After World War II, both Lionel and American Flyer introduced knuckle couplers, which look more like the couplers on real trains. Marx followed suit, although the Marx knuckle coupler is a single piece of plastic that doesn’t operate automatically. The Marx knuckle also won’t couple with Lionel knuckle couplers, but the Marx design is compatible with its tab and slot couplers. The tab fits securely enough into the knuckle that the two will stay together.

You can’t connect a Marx tilt coupler with a knuckle coupler directly, but you can connect a car with tab and slot couplers between the two in order to run all three together. Marx did a good job of keeping its various coupler types compatible with each other.

Marx made knuckle couplers from 1953 to 1974. Sometimes people refer to these as PKC, which stands for plastic knuckle coupler. Marx used the PKCs in its less expensive sets.

Now for some trivia: Scientific Toys makes a plastic train under the Eztec brand that somewhat resembles Marx’s least expensive plastic trains. Its coupler happens to be compatible with both Marx and Lionel knuckle couplers, though it won’t couple with a Marx tab and slot coupler. Installing an Eztec knuckle coupler on a Marx car increases its versatility.

Compatible with: tab in slot couplers

One-way

Marx’s one-way couplers are ugly but functional. One coupler is a simple post, and the other coupler is a pincher or claw that tightly grabs the adjacent post. If you turn a car around, it won’t connect, unlike other Marx designs. That’s why they call them a one-way coupler. This makes operations with this type of coupler difficult, since you have to be careful which way each car is facing, unlike real railroads, and unlike most competing designs.

Their design allows for automatic operation and they are very reliable. , but they were expensive to make because they had so many intricate parts. Assembling and installing them was very labor intensive. They also weren’t compatible with anything else Marx made. Furthermore, if a curious child took one of these couplers apart, it’s entirely possible a parent wouldn’t be able to figure out how to put it back together.

Another drawback with these couplers is that once they rust, they can stop working. A little bit of oil usually frees up the pincher fairly quickly.

This coupler isn’t very popular, even today. I think it’s more reliable than the fork coupler, but the fork coupler is more subtle. Subtlety is a virtue when it comes to couplers, so it was the more enduring of the two designs. Marx only made these from 1938 to 1942.

I frequently find cars with broken one-way couplers. Here are some tips for fixing them.

Conversion cars

When you have cars with incompatible coupler types, pick up a couple of beater cars with different types of couplers and swap them around. I’ve done this with several types of couplers so I can combine almost any make of train car I want.

Here’s my early approach with a Marx-Lionel conversion car, and a later effort for some cars that can convert between multiple types.